What is “Tongue and Groove”?

What is “Tongue and Groove”?

Most hardwood floors use tongue and groove fittings and it’s the system we prefer at 3 Oak Flooring. It works equally well with out engineered wood boards and our own 3 Oak Solid Flooring.

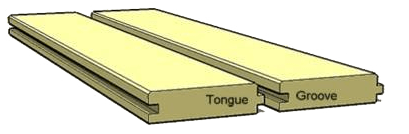

Tongue and groove planks are made to interlock with a unique woodworking joint. One length of the board has a long groove, while the other has a protruding “tongue”. Each board slots perfectly into its neighbour, with adequate space to spread an adhesive and ensure a tight fit. These types of joints are almost impossible to make onsite, and all of our flooring is sourced with the tongue and groove system already machined into the wood by skilled craftsmen.

Benefits of Tongue and Groove Flooring

With tongue and groove flooring, the boards are held securely together without the need for excessive gluing or nailing. Tongue and groove floors are impressively strong and once the finishing coat is applied, the entire surface is water-tight. That really helps to reduce excessive moisture that can swell the boards and lead to unsightly cupping.

Disassembling a tongue and groove floor without breaking the joints can be very difficult as most are either glued or nailed together. Boards that have been distorted by humidity may also be difficult to position. Nonetheless, this is an exceptionally efficient way of securing both engineered and solid wood planks over a wood-based, vinyl, tile or concrete subfloor.

We use three different methods to secure our tongue and groove flooring. The joints are either glued, affixed with hidden nails, or simply “floated” over the subfloor. Each method results in a tight-fitting and aesthetically beautiful floor that will withstand years of daily wear and tear.